Motivation

Clinical Need

There has been a rising concern regarding the inability of the FDA to thoroughly screen medical devices in the past decade. The alarming number of over 80,000 deaths and 2 million injuries caused by recalled medical devices since 2008 have only highlighted the need for improving medical device quality assurance methods of testing. Often times, these medical device failures can be credited due to micro-defects that can be found inside the products and within its material.

Current forms of non-destructive testing

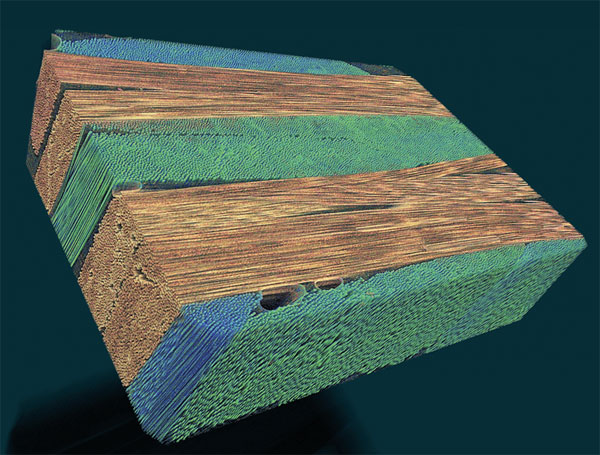

One of the commonly used forms of non-destructive testing for the quality assurance of biomedical devices include x-ray radiology testing. While useful, this popular technology is unable to image the micro-defects in materials that can be the leading cause of unexpected product failure. On the other hand, micro-CT systems are a form of x-ray radiology that is able to detect these defects on the micron scale. Both methodologies are typically imaged in black and white, making it difficult to differentiate between simple materials. By integrating a spectral detector with a micro-CT systems, Grayink can provide a more useful and colorful resolution to make product inspection more thorough.

Competitor Analysis

Our distinct system comes from the ability to fit parts in a custom manner based on whatever a user needs, subsequently contributing towards a high modularity. Additionally, through the Cadmium Telluride (CdTe) detector and integrated motion control system, the scan maintains high resolution and detection rates through zooming into defect areas. This compares favorably with the systems of other competitors such as Yxlon and Thermo Fischer Scientific, which have low modularities, Smiths detection, which has low detection rates, and Rapiscan Systems, which only has average detection rates even though its modularity level is good.

Marketing Strategy

Our system’s use cases are for science, research, and electronics within a $500 million market for micro-focus radiography systems that has an annual growth rate of 9.2%.

Learn more about our project here!